All workplaces that handle chemical hazards are required to carry out an assessment and risk evaluation of the chemical products they use. Risk assessment forms a core part of systematic health and safety management and plays a vital role in identifying and managing potential hazards associated with daily operations. In this article, we’ll walk you through how to carry out a risk assessment for chemical products – and what to keep in mind along the way.

What Does the Law Say About Risk Assessment of Chemical Products?

Under health and safety legislation, employers are legally required to assess the risks associated with hazardous substances used in the workplace. This includes evaluating how chemical products are handled, stored, and used – and what potential impact they may have on health and the environment. In the UK, these requirements are primarily regulated under COSHH (Control of Substances Hazardous to Health). The purpose is to ensure that suitable precautions are taken to protect workers and others from exposure to harmful substances.

Konsulttjänster

Årligt riskbedömningsstöd

Vi erbjuder en riskbedömningstjänst där våra konsulter genomför riskbedömningar på samtliga av era kemikalier, med årlig återkommande uppdatering.

Why Risk Assessments Are Important

Carrying out risk assessments is essential for several reasons. First and foremost, they help reduce the likelihood of chemical hazards causing harm or accidents in your workplace. A thorough risk assessment enables you to identify and prioritise actions, so you can tackle the most significant risks first. Documenting the assessments also allows for comparisons over time, supporting a structured and ongoing approach to workplace health and safety.

It is vital that all relevant employees are provided with enough information to work in a safe environment. That’s why it’s risky to use chemical products without conducting a prior assessment. The risk assessment provides a written basis outlining the hazards involved in handling specific substances. This information is key to implementing the right protective measures to safeguard your employees.

Neglecting or carrying out inadequate assessments can lead to serious health consequences due to unintended exposure. Without an active approach to risk management, the chances of incidents or illnesses increase – such as chemical burns or allergic reactions.

Finally, it’s also important to be able to present your risk assessments during inspections by authorities. While the primary purpose of a risk assessment is to protect workers and create a safe working environment, this is yet another reason why assessments should always be properly documented and conducted systematically.

Utbildning

Riskbedömning av kemiska produkter

Utbildningen ger grundläggande kunskaper för att genomföra riskbedömningar där kemiska produkter är involverade eller andra kemiska riskkällor finns.

Preparing for a Chemical Risk Assessment

Before starting a risk assessment of chemical products, it’s important to ensure you have all the necessary information in place. The preparation phase involves gathering details about work processes, equipment, and how substances are used and handled. This information forms the foundation for identifying and breaking down the potential hazards involved in the handling of chemicals.

Make sure you have:

- An up-to-date chemical inventory to ensure no substances are overlooked in the assessment.

- Access to the most recent version of each product’s safety data sheet (SDS).

- Identified any other sources of chemical risk.

- Collected input from employees – especially those directly involved in the tasks being assessed.

This groundwork ensures your risk assessment is accurate, relevant, and tailored to actual working conditions.

Riskbedömningar görs inte per kemisk produkt utan per aktivitet. Alltså behöver du göra separata bedömningar för samma kemikalie om den används i flera olika scenarion där hantering eller miljö skiljer sig åt.

Step-by-Step – How to Conduct a Chemical Risk Assessment

Now that you’ve completed the preparations and have a clear overview of the chemicals used in your organisation – along with the applicable regulations – it’s time to carry out the actual risk assessment.

Here’s a step-by-step guide:

Step 1: Review Key Sections of the Safety Data Sheet (SDS)

Begin by reviewing the most relevant sections of the safety data sheets, as they contain essential information for the risk assessment:

- Hazard identification (Section 2)

- First-aid measures (Section 4)

- Accidental release measures (Section 6)

- Handling and storage (Section 7)

- Exposure controls / personal protection (Section 8)

- Disposal considerations (Section 13)

If you are assessing a substance with a workplace exposure limit (WEL), Section 3 is also important for identifying how much of the substance is present. For flammable substances, Section 5 (Fire-fighting measures) may also be relevant.

If anything is unclear or if additional information is needed, the SDS will provide contact details for further assistance.

Step 2: Combine Workplace Insights with SDS Data

The next step involves reviewing the information gathered from employees, alongside the SDS data, to create a comprehensive picture of the risks involved.

Key questions to address during the assessment include:

- How might workers be exposed to the hazardous substance? How frequently and for how long?

- Are there potential reactions with materials or other chemical hazards?

- Have any previous incidents or near misses occurred?

- Are there any specific requirements for the chemical? (e.g. special handling for sensitisers or substances that are carcinogenic, mutagenic, or toxic to reproduction – CMRs)

- How effective are existing protective measures? Is the risk to health, safety, or the environment considered low or high? Is it acceptable based on handling instructions?

- Are there WELs (workplace exposure limits) for substances in the product, and is there a risk of exceeding them?

- You are legally required to assess and document whether the exposure level in the workplace is acceptable in relation to the WEL. If it’s unclear whether the exposure is below the limit, air monitoring must be carried out.

- Evaluating exposure against WELs is often one of the most complex aspects of chemical risk assessment. It is strongly recommended to involve someone with appropriate expertise when making these evaluations.

Step 3: Evaluate the Outcome and Take Action

Once your risk assessment is complete, reflect on the results:

- Are the risks at an acceptable level, or are further actions needed?

- Could risks be reduced or eliminated by changing the way the task is performed?

- Develop an action plan and decide on any necessary control measures.

- Follow up on the risk assessment and ensure that the risks remain at a manageable level over time.

A structured approach like this supports safer chemical handling and helps you meet both legal and practical requirements for a healthier work environment.

What to Keep in Mind After Completing Your Risk Assessment

Once the risk assessment has been completed, documented, and signed, it’s important that it is easily accessible to the relevant employees – ideally stored near the location where the assessed risk exists. In iChemistry, you can store your risk assessments digitally, giving users instant and convenient access when needed.

If your risk assessment identifies a risk to health in the workplace, your first step should always be to try to eliminate it. If that’s not possible, you must take steps to reduce the risk as much as reasonably practicable.

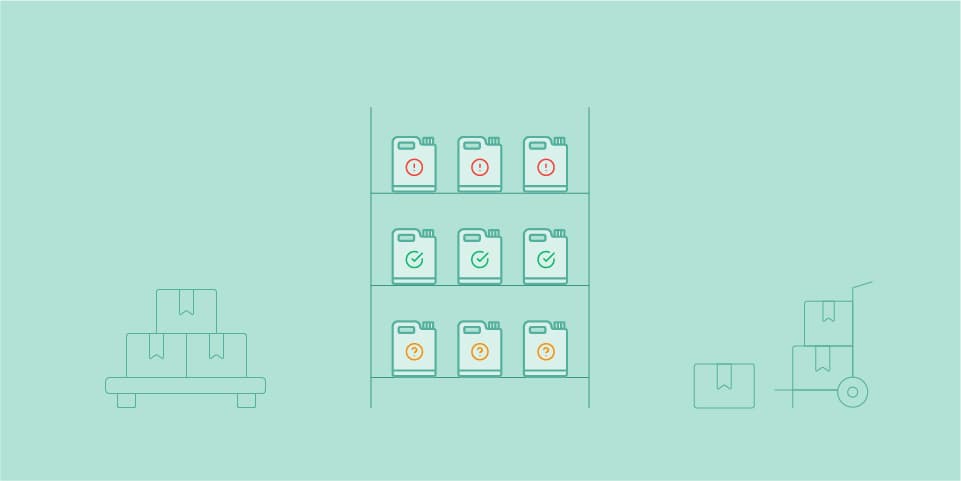

The outcome of the risk assessment forms a prioritised list of hazards – highlighting which risks require immediate action and which are considered acceptable. High-priority risks should be addressed first. Actions may include anything from substituting a hazardous substance to improving ventilation or upgrading personal protective equipment. Make sure all actions are tracked and reviewed at appropriate intervals.

If significant changes occur in your operations, you must revisit your risk assessments to ensure no new unacceptable risks have emerged. Risk assessments for chemical products should be reviewed regularly and updated whenever there are changes to substances, work methods, or other relevant workplace conditions.

Do you have any questions? We are here!

Our EHS consultants have extensive experience in safety data sheets and substitution work and are here to help you enhance safety and comply with legal requirements. We also offer training in environmental and workplace legislation, REACH, chemical management, and risk assessment.

Do you have any questions? Don’t hesitate to contact us by clicking the button below or emailing us directly at consulting@intersolia.com.